We first had the idea to automate manual vaccination in 2003. We won a UK Government SMART grant to look at the feasibility of building a system that could do this. We wanted a machine driven by a vision system that could recognise individual features on a fish and from those features, determine the vaccination point. This project made us realise we were too far ahead of the curve and technology would have to take a big leap forward for us to realise our idea.

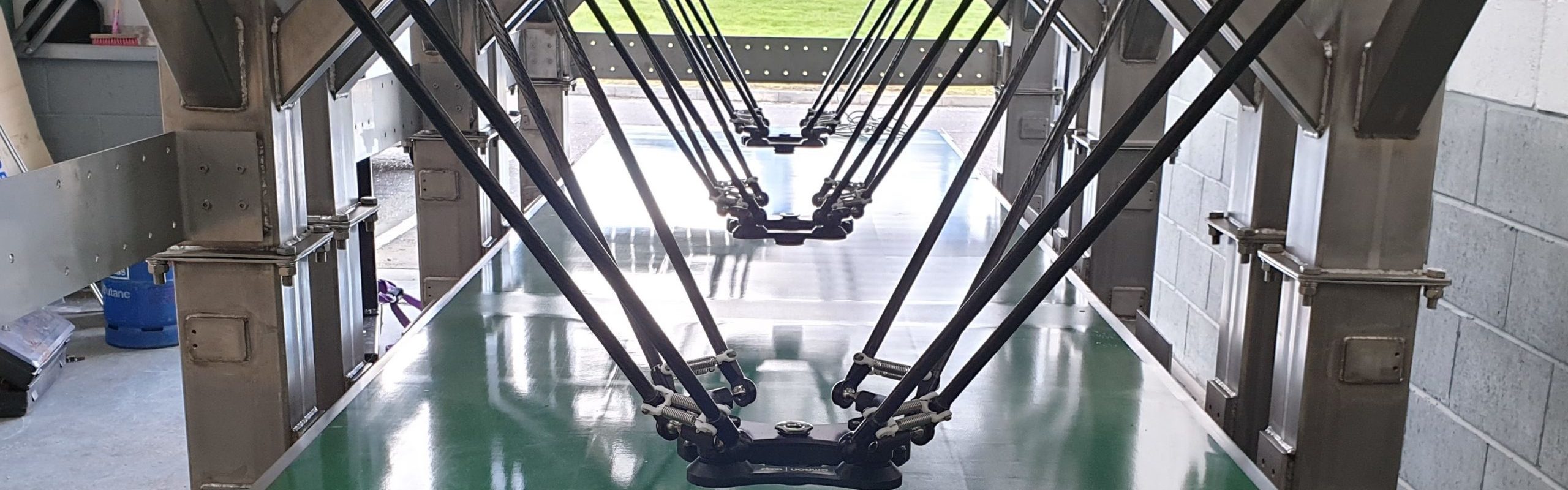

Fast forward to 2013 when we started to take a serious look at automation again as there had been huge advances in vision systems, algorithm development and robotics. From 2013 onwards we started to develop the idea and in 2017 we were confident enough to commission the building of a proof-of-concept system called “The Inocubot”.

The success of this system allowed us to build a three-robot commercial prototype with funding from the Scottish Government and a small equity raise. The coronavirus interrupted our planned roll out of this system but we are now getting back on track and plan to roll out the first system for Q4 2021.

We have also received funding to develop this concept into a system for vaccinating fish from 5 grams to 20 grams to support hatcheries where early vaccination is required. This work is ongoing.

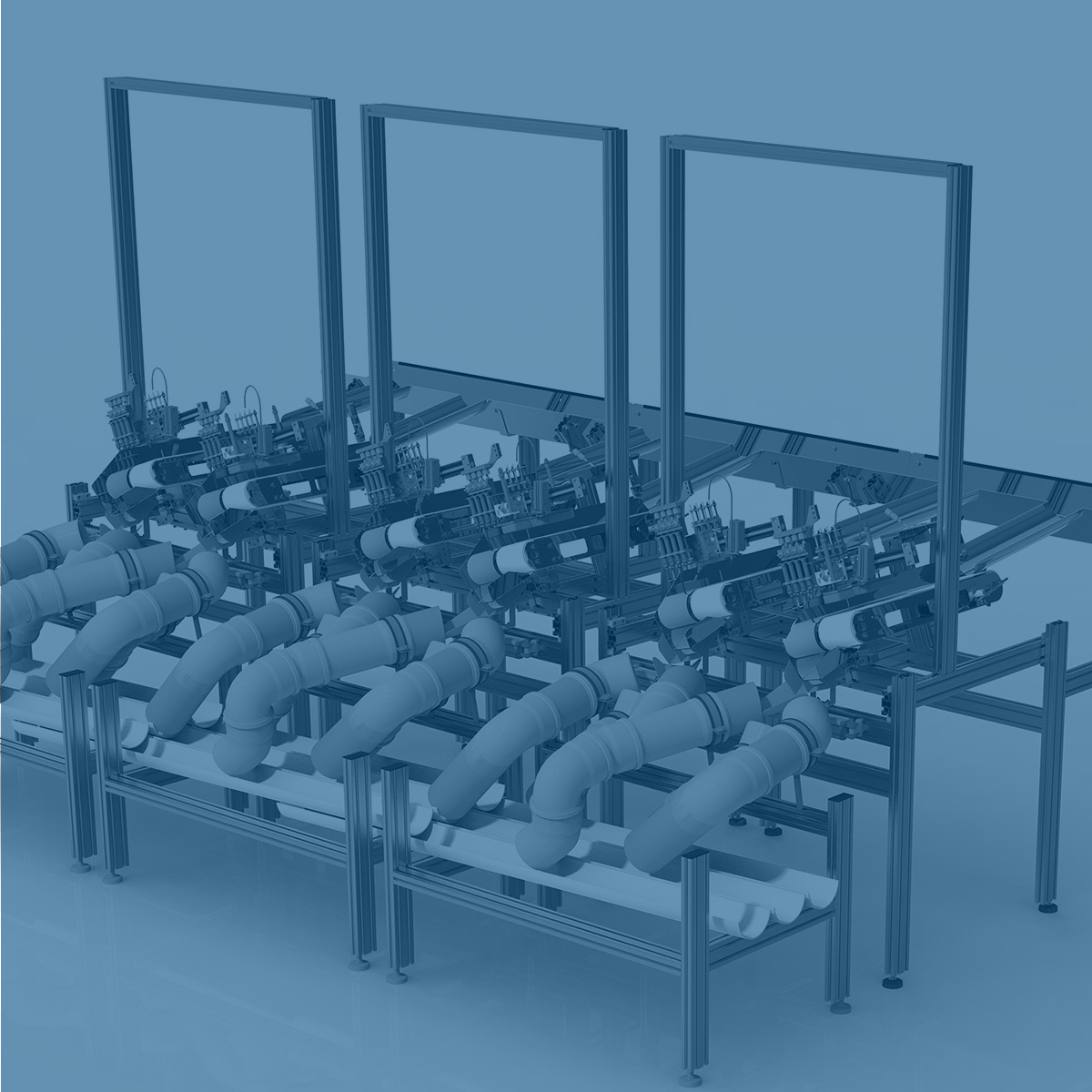

Inocubot Key Features:

- A typical 6 Inocubot setup vaccinates 21,600 fish per hour

- No specialist training is required for operation

- Patented end-of-arm tool, capable of delivering up to 3 IP vaccines in one shot

- Simultaneously delivers IM shot with IP shot

- Imaging take allowing you to record all your stock

- Fish are automatically graded into their various sizes

- Easily identify and discard fish with fin rot or damaged operculumo.

Flexible:

- Farmers have control over when they vaccinate

- No reliance on hand vaccination teams being available

- Rapid new product development is enabled by only having to adapt the end of arm tool.

Data insights:

- Each fish can be health checked against set parameters via image analysis

- Vaccine producers can access images for each fish vaccinated, so will be able to data mine a huge data set looking for early signs of disease and determining health.

Inocubot Key Benefits

- Only 2 staff are required to operate Inocubot

- Automation frees up staff for other areas

- Easy to operate in compliance with social distancing

- No need to wait for vaccination teams, work to your timetable

- Imaging can allow individual fish tracking with digital IDs

- Images make it possible to check fish health using set parameters

- The potential foundation of your own farm management system

- Data gathered helps improve future vaccination strategies

- Helps cut Aqualife travel by 50% and associated climate impact

- Less strain on the farm’s facilities and operations

- Covid friendly, fewer operators mean less chance of virus transmission.